Products

- Intro

- Ranges

- Specifications

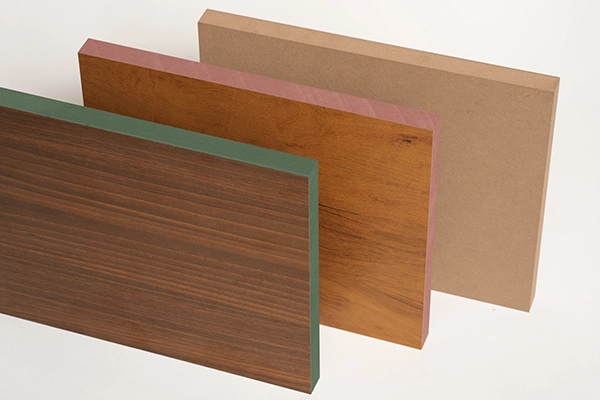

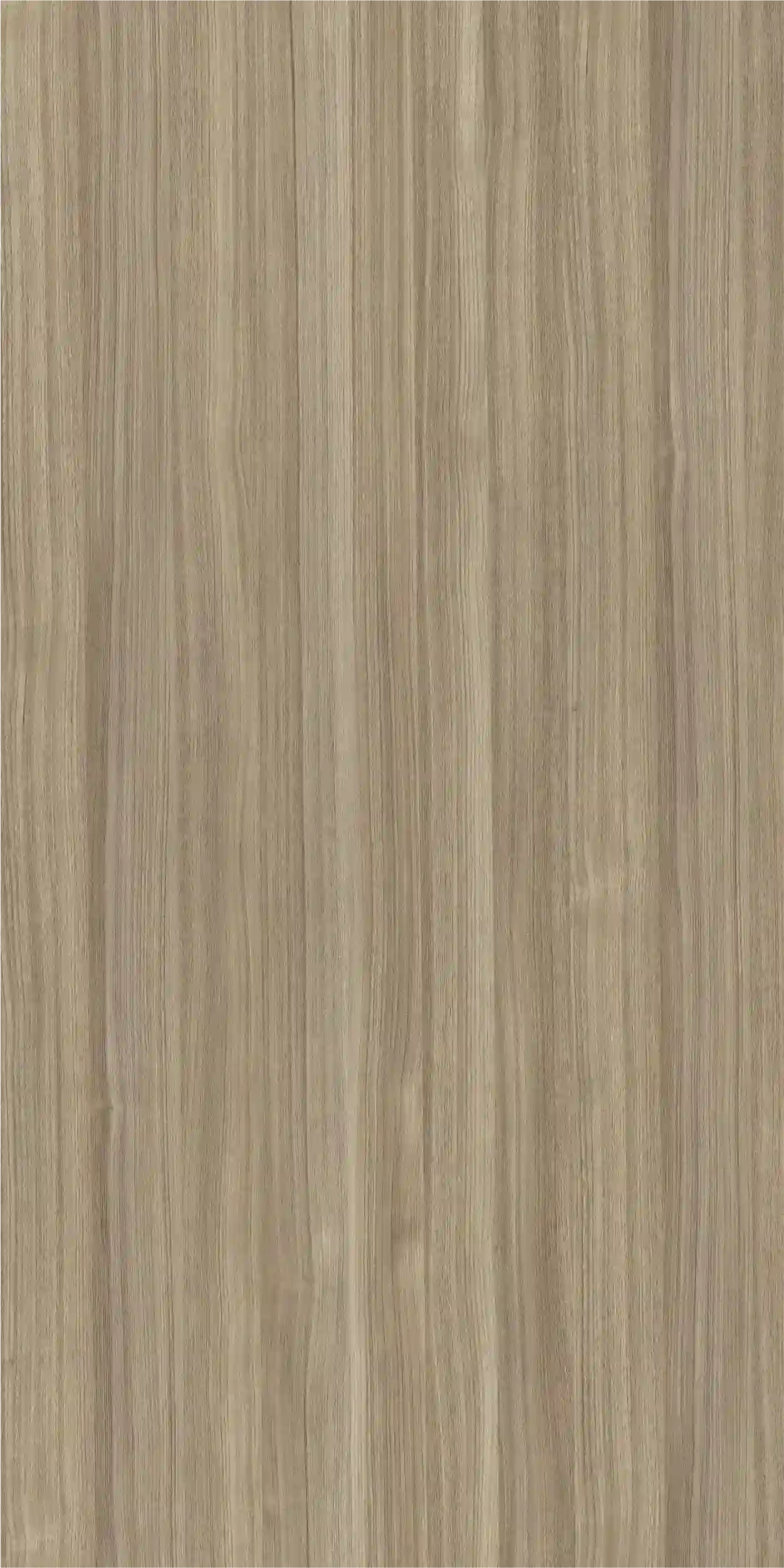

ARTESA Pre-Laminated MDF

Introducing the ARTESA Pre-Laminated MDF Board by E3 - a harmonious blend of durability and design excellence. As a leading pre laminated MDF board manufacturer, E3 crafts these boards to meet the highest standards of quality and aesthetics.

Engineered for exceptional moisture resistance, scratch resistance, and the ability to withstand abrasion, cracks, and stains, ARTESA boards are ideal for applications where dimensional stability is crucial. Whether it's kitchen cupboards, cabinets, or bathroom installations, these boards ensure longevity and low maintenance.

As prominent laminated board manufacturers, E3 offers ARTESA Pre-Laminated MDF in various grades, including HDMR, Exterior Grade MDF, and Interior Grade MDF, Boil Guard, etc. Available configurations encompass one-side laminated, both-side laminated, one-side bare, and both-side balancing, providing versatility to suit diverse project requirements. Explore the ARTESA range and experience the difference that quality craftsmanship brings to your spaces. With E3, you're not just choosing a product; you're investing in excellence.

| THICKNESS (mm) | SIZE: |

| 4mm to 25mm Interior Grade MDF 5.5mm to 25mm Exterior Grade MDF 5.5mm to 18mm HDMR 5.50mm to 18mm Boil Guard |

2440mm x 1220mm |

| TECHNICAL SEPCIFICATIONS | ||||||

| S.No. | Test | Unit | HDMR | Exterior | Interior | Boil Guard |

| 1 | Density | kg/m3 | 850-900 | 700-800 | 700-800 | >1000 |

| 2 | Variation from mean density | % | ±10 | ±10 | ±10 | ±10 |

| 3 | Moisture Content | % | 4.0-8.0 | 4.0-8.0 | 4.0-8.0 | 4.0-8.0 |

| 4 | Variation from mean moisture content | % | ±3 | ±3 | ±3 | ±3 |

| 5 | Thickness Swelling in 24 hrs (Max) | % | Up to 20 | Up to 35 | Up to 35 | ≤2 |

| 6 | Modulus of rupture (Min) | N/mm2 | ||||

| a) up to 20mm Thickness (Average) | 30-35 | 22-27 | 18-23 | >50 | ||

| b) Above 20mm Thickness (Average) | 25-30 | 15-22 | 15-18 | >48 | ||

| 7 | Modulus of elasticity (Min) | N/mm2 | ||||

| a) up to 20mm Thickness (Average) | 2600-3200 | 2300-2800 | 2100-2800 | >5500 | ||

| b) Above 20mm Thickness (Average) | 2100-2600 | 1900-2300 | 1700-2100 | >5000 | ||

| 8 | Internal bond strength (Min) | N/mm2 | ||||

| a) up to 20mm Thickness (Average) | 0.90-1.20 | 0.60-0.70 | 0.55-0.65 | >2.0 | ||

| b) Above 20mm Thickness (Average) | 0.80-1.10 | 0.50-0.60 | 0.50-0.55 | >2.0 | ||

| 9 | Internal bond strength (Min) | N/mm2 | ||||

| a) After cyclic Test | 0.12-0.35 | 0.10-0.35 | NA | >1.0 | ||

| b)After AWR | 0.12-0.20 | 0.10-0.20 | NA | >1.0 | ||

| 10 | Screw withdrawal strength (Min) | N | ||||

| a) Face | 3000 | 1250 | 1250 | ≥4000 | ||

| b) Edge | 2300 | 850 | 700 | ≥2600 | ||

| 11 | Surface abrasion (Min) | |||||

| a) Type - 1 | 1000 | 1000 | 1000 | 1000 | ||

| b) Type-2 | 450 | 450 | 450 | 450 | ||

| c) Type - 3 | 250 | 250 | 250 | 250 | ||

| d) Type - 4 | 75 | 75 | 75 | 75 | ||

| 12 | Resistance to steam / water vapours | No blister, delamination or change in surface finish | ||||

| 13 | Resistance to Crack | No sign of crack or delamination | ||||

| 14 | Resistance to cigarette burn | No mark or stain on the specimen after cleaning with water or solvent | ||||

| 15 | Resistance to stain | No stain on the specimen after cleaning with water or detergent | ||||

| 16 | Formaldehyde content (Fc) | mg/100 g for oven dry board | Formaldehyde Class, E1 : Fc≤8 | |||

| Formaldehyde Class, E2 : 8<Fc≤30 | ||||||

.webp)

.webp)