- Intro

- Ranges

- Specifications

E3 Pre-Lam

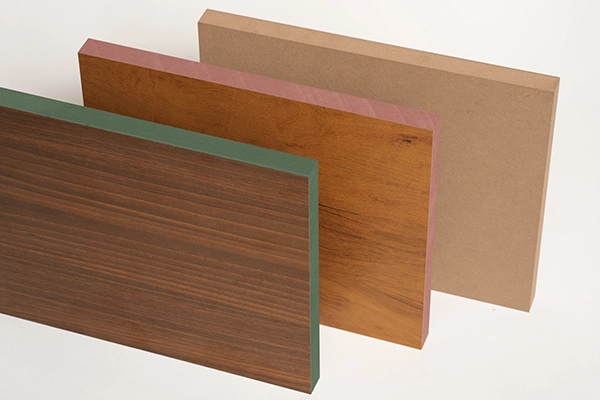

Introducing E3 Pre-Lam boards - a harmonious blend of durability and design excellence. As a leading pre-laminated MDF board manufacturer, E3 crafts these boards to meet the highest standards of quality and aesthetics.

Our pre-lam boards feature German paper laminates and are available in many shades, designs, and colours. Our board is extra dense, extra strong, anti-fungal, water-resistant, borer & termite, and eco–friendly.

As a prominent laminated board manufacturer, E3 Pre-Lam offers various grades, including HDMR, Exterior Grade MDF, Interior Grade MDF, Boil Guard, etc. We have one-sided laminated, both-sided laminated, one-sided bare, and both-sided balancing boards. For various types of projects-- from commercial to residential they are best. Look out our E3 Pre-Lam range and learn the difference that quality great craftsmanship brings to your spaces. With E3, you're not just choosing a product; you're investing in excellence.

| THICKNESS (mm) | SIZE: |

| 4mm to 25mm Interior Grade MDF 5.5mm to 25mm Exterior Grade MDF 5.5mm to 18mm HDMR 5.50mm to 18mm Boil Guard |

2440mm x 1220mm |

| TECHNICAL SEPCIFICATIONS | ||||||

| S.No. | Test | Unit | HDMR | Exterior | Interior | Boil Guard |

| 1 | Density | kg/m3 | 850-900 | 700-800 | 700-800 | >1000 |

| 2 | Variation from mean density | % | ±10 | ±10 | ±10 | ±10 |

| 3 | Moisture Content | % | 4.0-8.0 | 4.0-8.0 | 4.0-8.0 | 4.0-8.0 |

| 4 | Variation from mean moisture content | % | ±3 | ±3 | ±3 | ±3 |

| 5 | Thickness Swelling in 24 hrs (Max) | % | Up to 20 | Up to 35 | Up to 35 | ≤2 |

| 6 | Modulus of rupture (Min) | N/mm2 | ||||

| a) up to 20mm Thickness (Average) | 30-35 | 22-27 | 18-23 | >50 | ||

| b) Above 20mm Thickness (Average) | 25-30 | 15-22 | 15-18 | >48 | ||

| 7 | Modulus of elasticity (Min) | N/mm2 | ||||

| a) up to 20mm Thickness (Average) | 2600-3200 | 2300-2800 | 2100-2800 | >5500 | ||

| b) Above 20mm Thickness (Average) | 2100-2600 | 1900-2300 | 1700-2100 | >5000 | ||

| 8 | Internal bond strength (Min) | N/mm2 | ||||

| a) up to 20mm Thickness (Average) | 0.90-1.20 | 0.60-0.70 | 0.55-0.65 | >2.0 | ||

| b) Above 20mm Thickness (Average) | 0.80-1.10 | 0.50-0.60 | 0.50-0.55 | >2.0 | ||

| 9 | Internal bond strength (Min) | N/mm2 | ||||

| a) After cyclic Test | 0.12-0.35 | 0.10-0.35 | NA | >1.0 | ||

| b)After AWR | 0.12-0.20 | 0.10-0.20 | NA | >1.0 | ||

| 10 | Screw withdrawal strength (Min) | N | ||||

| a) Face | 3000 | 1250 | 1250 | ≥4000 | ||

| b) Edge | 2300 | 850 | 700 | ≥2600 | ||

| 11 | Surface abrasion (Min) | |||||

| a) Type - 1 | 1000 | 1000 | 1000 | 1000 | ||

| b) Type-2 | 450 | 450 | 450 | 450 | ||

| c) Type - 3 | 250 | 250 | 250 | 250 | ||

| d) Type - 4 | 75 | 75 | 75 | 75 | ||

| 12 | Resistance to steam / water vapours | No blister, delamination or change in surface finish | ||||

| 13 | Resistance to Crack | No sign of crack or delamination | ||||

| 14 | Resistance to cigarette burn | No mark or stain on the specimen after cleaning with water or solvent | ||||

| 15 | Resistance to stain | No stain on the specimen after cleaning with water or detergent | ||||

| 16 | Formaldehyde content (Fc) | mg/100 g for oven dry board | Formaldehyde Class, E1 : Fc≤8 | |||

| Formaldehyde Class, E2 : 8<Fc≤30 | ||||||

.webp)

.webp)